Planning & Mapping

Advanced Evaporative Cooling with Customized Air Duct Solutions

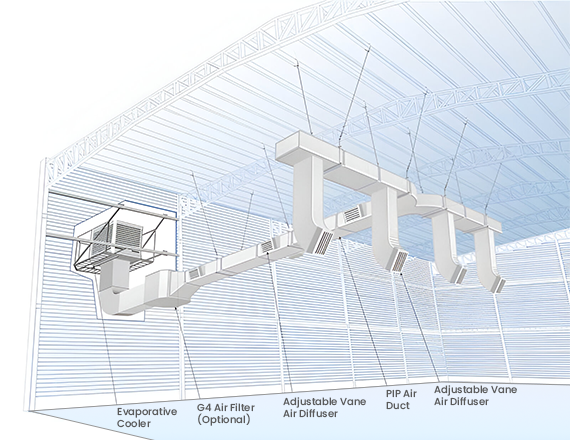

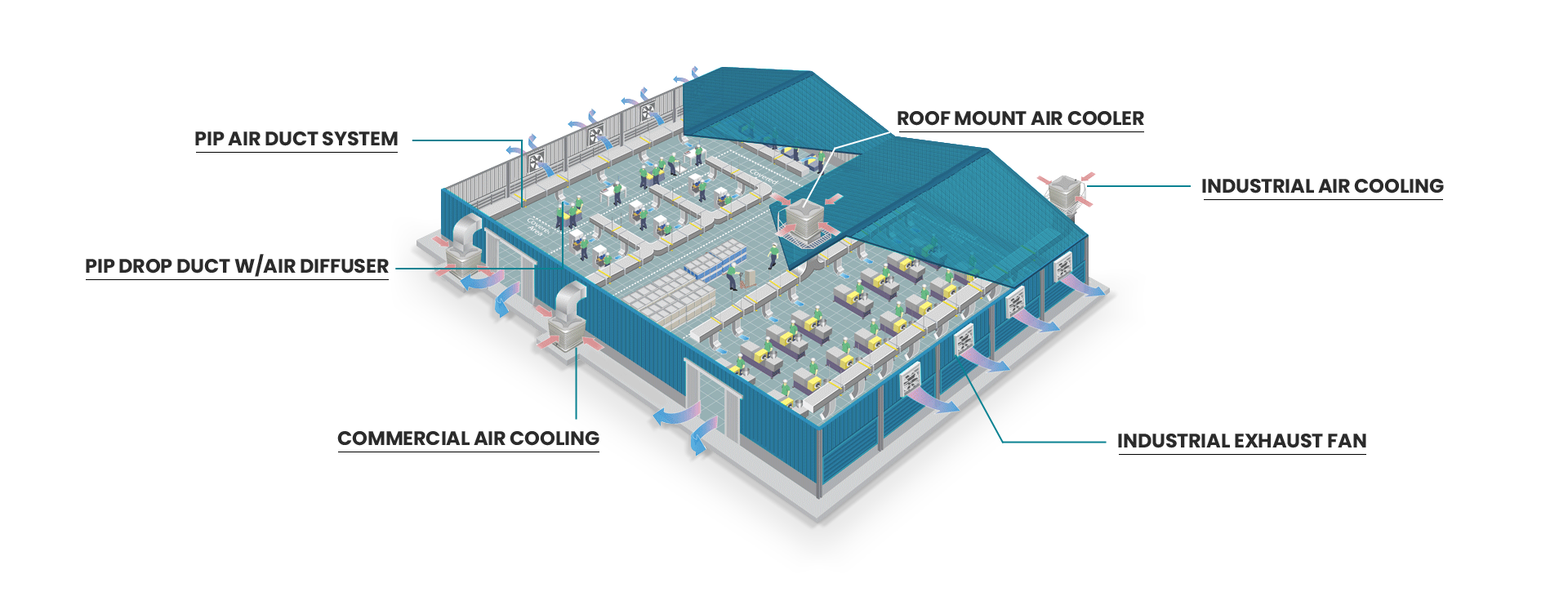

At Sky Air Cooler, we combine cutting-edge Evaporative Cooling Technology with tailored Air Duct Systems to deliver efficient, clean, and targeted cooling solutions for your industrial workspace. Our innovative Open Space Cooling System draws in fresh outside air, filters it thoroughly to ensure cleaner air quality, and cools it naturally through the evaporative process.

Powered by a high-performance built-in fan, the cooled air is pushed through a network of customized, lightweight, and insulated air ducts designed specifically for your unique workspace layout. This ensures that cool air is delivered directly to critical areas — whether it’s your employees’ workstations or sensitive equipment — providing instant comfort and enhanced productivity throughout the day.

Our system not only improves working conditions by maintaining a cooler environment but also promotes healthier air quality by filtering dust and pollutants before cooling. With Sky Air Cooler’s customized air duct design, you get:

- Efficient cooling targeted exactly where you need it

- Energy-saving evaporative cooling with minimal environmental impact

- Improved air quality for a healthier workspace

- Flexible installation tailored to your facility’s unique needs

What is an Industrial Air Cooler?

An industrial air cooler, also known as an evaporative air cooler, is a high-capacity cooling device designed to provide costeffective and energy-efficient cooling in large spaces such as factories, warehouses, workshops, manufacturing units, commercial kitchens, and other industrial environments. It works on the principle of evaporative cooling, where warm air is drawn through wet honeycomb pads, lowering its temperature before being circulated.

Factories & Manufacturing Plants

- Maintain comfortable temperatures for workers, improving productivity.

- Reduce heat generated from heavy machinery and processes.

Warehouses & Storage Facilities

- Keep stored goods, especially perishable and sensitive items, at optimal temperature.

- Control dust and improve air circulation.

Automotive & Engineering Workshops

- Cool down metal-intensive workspaces.

- Reduce the risk of overheating machinery and equipment.

Textile, Plastic, and Packaging Units

- Control ambient temperature and humidity levels.

- Prevent product warping and enhance process efficiency.

Agricultural Processing Units

- Maintain ideal conditions for food processing, packaging, and storage.

Event Venues, Cafeterias & Public Spaces

- Temporary cooling for exhibitions, events, and semi-open areas.

Temperature Decrease of Evaporative Air Cooler

| Exit °C / Intake Air °C | 10% | 20% | 30% | 40% | 50% | 60% | 70% | 80% | 90% |

|---|---|---|---|---|---|---|---|---|---|

| 10 | 3.2 | 4.0 | 4.8 | 5.6 | 6.4 | 7.2 | 8.0 | 8.6 | 9.4 |

| 15 | 6.6 | 7.8 | 8.8 | 9.8 | 10.8 | 11.7 | 12.6 | 13.4 | 14.3 |

| 20 | 10.1 | 11.4 | 12.8 | 13.9 | 15.2 | 16.2 | 17.2 | 18.2 | 19.2 |

| 25 | 13.4 | 15.0 | 16.6 | 18.0 | 19.4 | 20.6 | 21.8 | 22.9 | 24.0 |

| 30 | 16.6 | 18.0 | 20.4 | 22.0 | 23.6 | 25.0 | 26.4 | 27.7 | 28.9 |

| 35 | 19.8 | 22.2 | 24.2 | 26.2 | 28.0 | 29.6 | 31.0 | 32.4 | 33.7 |

| 40 | 23.0 | 25.6 | 28.1 | 30.4 | 32.3 | 33.9 | - | - | - |

| 45 | 25.9 | 29.2 | 32.0 | 34.4 | - | - | - | - | - |

| 50 | 29.0 | 32.7 | 35.8 | - | - | - | - | - | - |

Compare With Other Cooling Or Ventilation Devices

| Type | ||||

|---|---|---|---|---|

| Evaporative Cooler | Refrigerative Air Con | Centrifugal Fan | Ceiling Fan | |

| Capacity | 18000 Cmh | 400000 Btu/Hr | 40000 Cmh | 1400 Mm.Dia |

| Power | 1.1 Kw | 54 Kw | 7.5 Kw | 0.075 Kw |

| Cover Area | 1000 Sq.Ft. | 1000 Sq.Ft. | 1000 Sq.Ft. | 1000 Sq.Ft. |

| Air Change Per Hour | 30 | 0 | 30 | 0 |

| Units Required | 8 | 2 | 3 | 83 |

| Total Kw | 8.8 Kw | 108.0 Kw | 22.5 Kw | 6.2 Kw |

| Electricity Cost Per Year (10 Hrs, 365 Days) |

32120 Kw-H | 394200 Kw-H | 82125 Kw-H | 22721 Kw-H |

| Cost With Reference To Refrigerative Air Con |

8.15% | 100% | 20.83% | 5.76% |